Industries

Contact with

us for any

Design Solutions

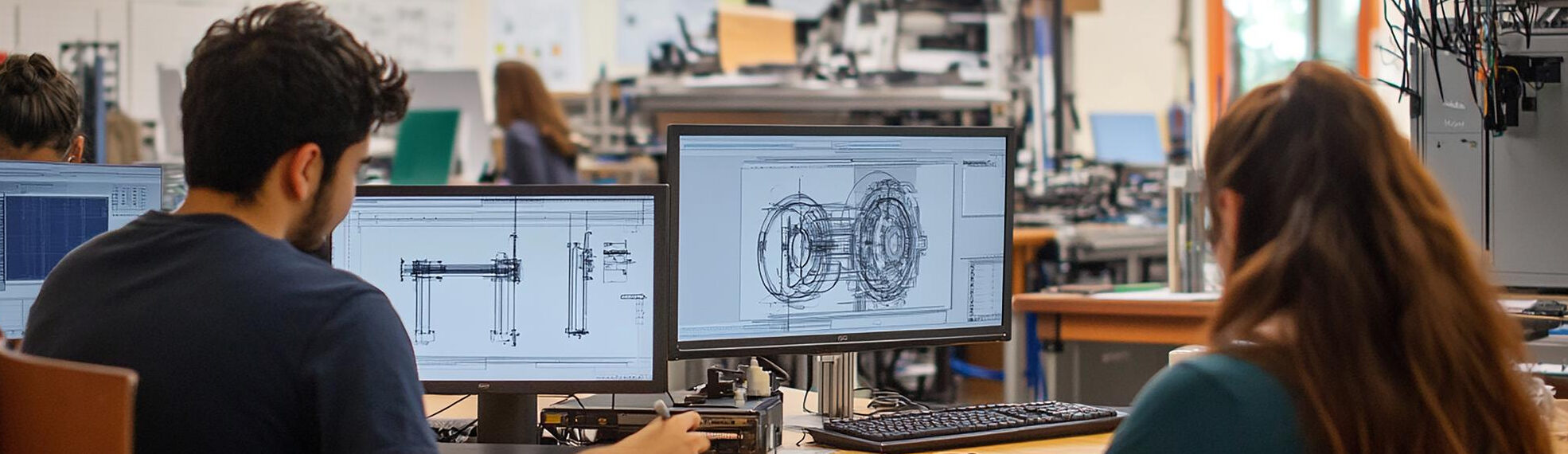

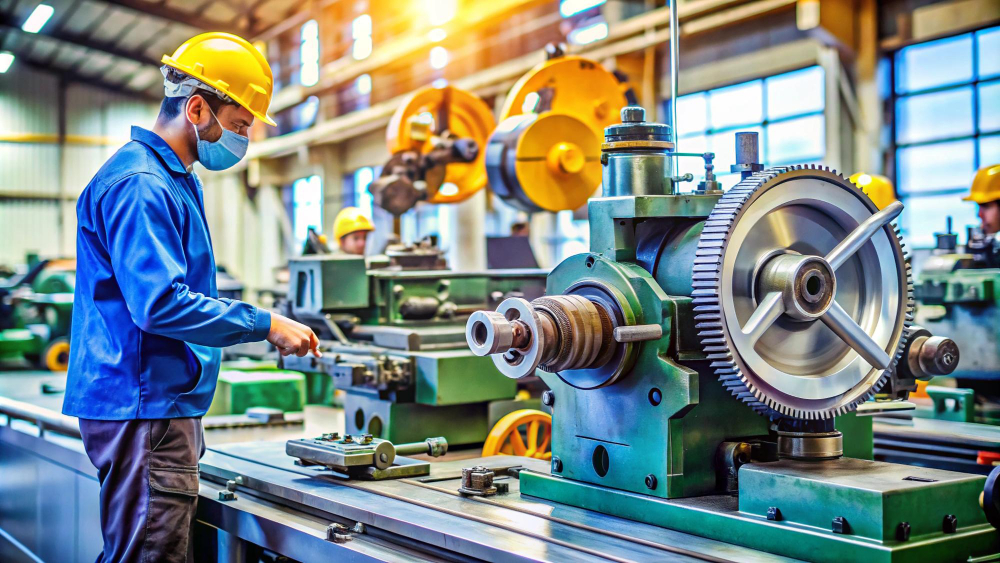

Advanced Machine Design and Manufacturing Engineering Solutions

At Lamis Technology, we deliver world-class machine design and manufacturing engineering services that help industries automate, optimize, and scale production with precision. Our experience spans across special purpose machines (SPMs), production tooling, assembly fixtures, and material handling systems, empowering manufacturers to achieve higher productivity, quality, and efficiency.

We combine deep mechanical engineering expertise with process automation and digital validation tools to create machines that are reliable, safe, and cost-effective. From design concept to commissioning, every system is engineered for performance and manufacturability.

What we do

Our Capabilities

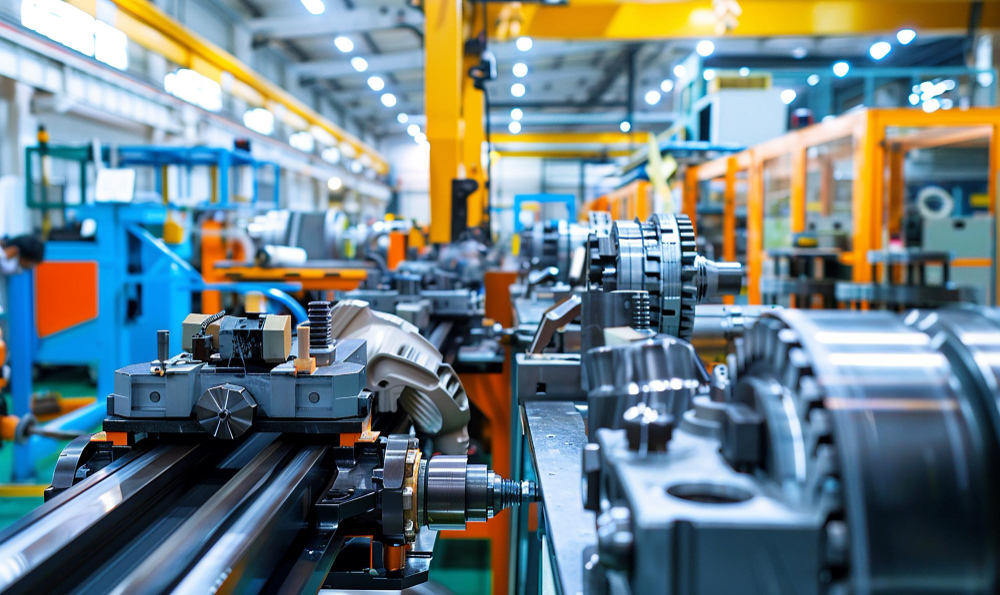

SPM Design & Development: high-precision, automated, and semi-automated machines for assembly, testing, and processing applications

Tooling & Fixture Engineering: jigs, checking fixtures, welding fixtures, and robotic tooling for mass production

Assembly Line Design: process planning, layout optimization, cycle time reduction, and ergonomics

Material Handling Systems: racks, carts, conveyors, and robotic pick-and-place systems for streamlined logistics

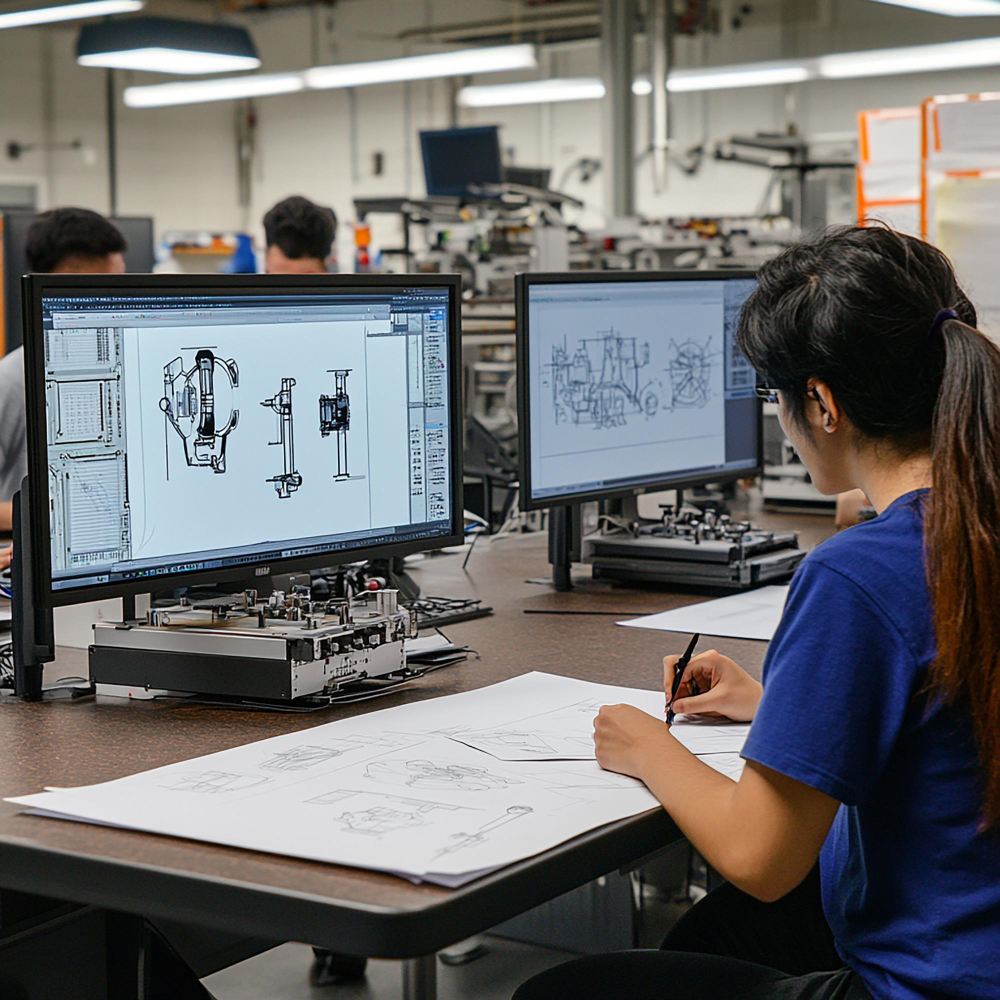

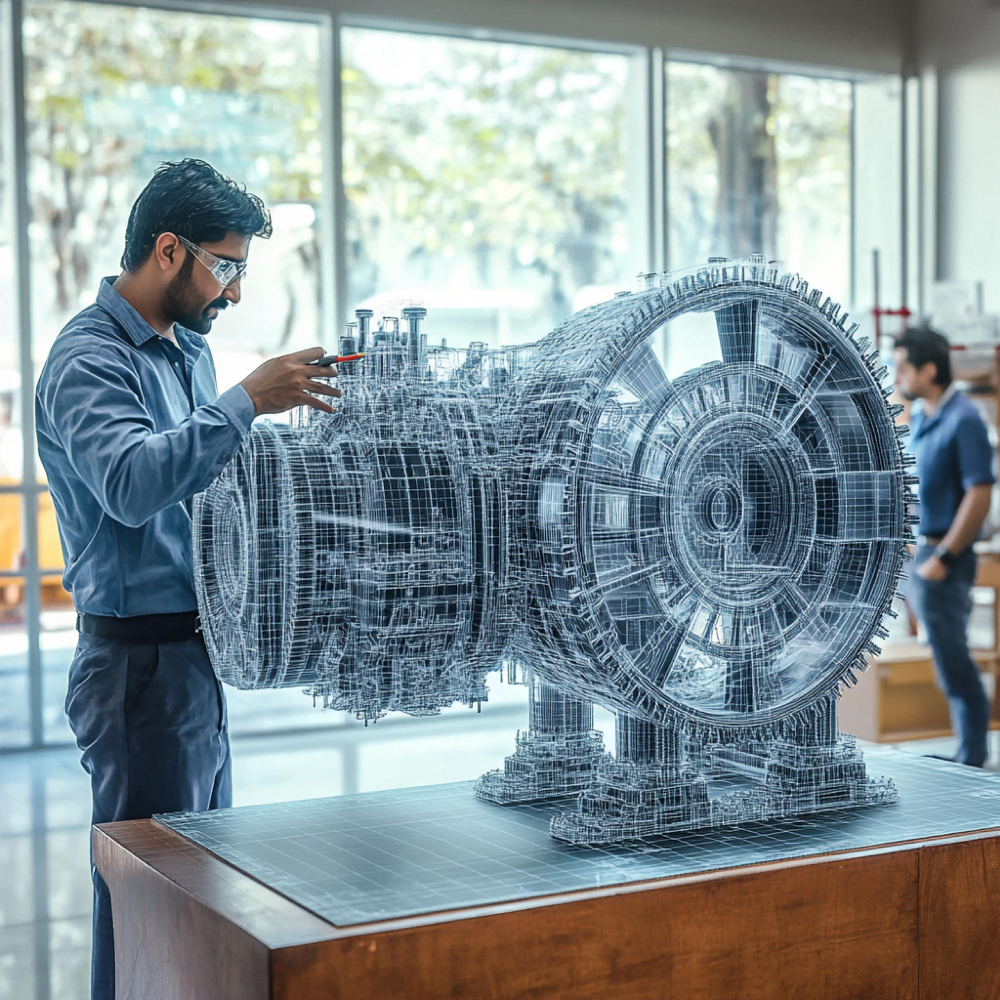

Digital Validation: offline programming, motion simulation, and virtual commissioning using digital twin technology

Prototyping & Low Volume Manufacturing: pilot machines and pre-production tooling to validate processes before scale-up

Toolchain

Deliverables

Measurable benefits

Use cases we support