Industries

Contact with

us for any

Design Solutions

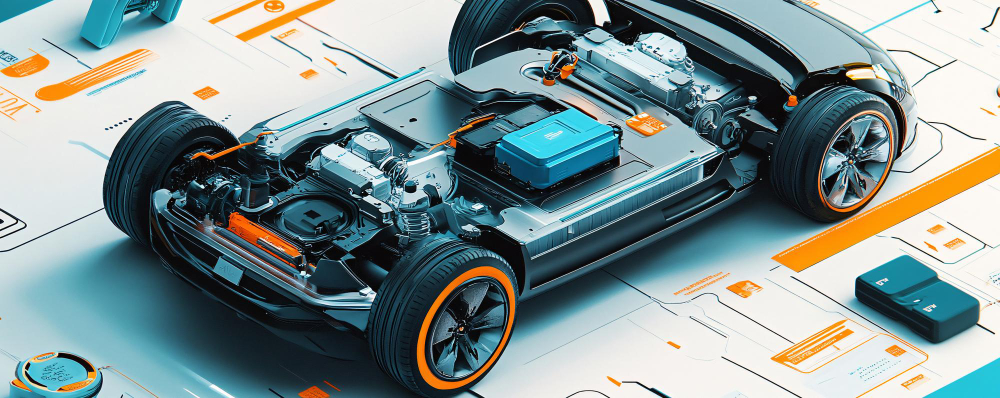

Electric Vehicle Design and Engineering Solutions

Lamis Technology is a trusted engineering partner to OEMs, Tier 1 suppliers, and EV startups, delivering full-spectrum electric vehicle design and product development services. Our goal is to accelerate the transition to cleaner mobility by engineering EV systems that are efficient, safe, and ready for scalable production.

We bring together expertise in vehicle architecture, battery systems, thermal management, and lightweight structures—supported by advanced simulation and manufacturing engineering tools. Every project is driven by innovation, precision, and sustainability.

What we do

End-to-end EV design and product engineering

Powertrain electrification, battery integration, and thermal systems

Manufacturing process design, tooling, and virtual validation

R&D support for EV components and system optimization

Our Capabilities

- EV Architecture Development: vehicle layout, weight distribution, system packaging, and integration

- Powertrain & Battery Systems: e-axle, motor mounts, battery enclosure, BMS integration, cooling & safety studies

- Chassis & Body Design: lightweight materials, composite structures, occupant protection analysis

- Thermal Management: cooling circuits, HVAC optimization, heat dissipation & CFD simulation

- Simulation & Validation: structural, crash, and thermal performance; range & efficiency optimization

- Manufacturing Engineering: tooling design, automation systems, and digital twin validation

Toolchain

CATIA V5

NX

Creo

SolidWorks

HyperMesh

LS-DYNA

Simcenter

Deliverables

CAD and CAE data with validation reports

Battery system layout and cooling simulation

DVPR and safety compliance documentation

Manufacturing feasibility and tooling design packages

Measurable benefits

Accelerated EV program development

Improved energy efficiency and reduced vehicle weight

Lower cost of validation via simulation-first approach

Reliable, safe designs ready for global compliance

Use cases we support

Clean-sheet EV platform engineering

ICE-to-EV conversions

Battery and powertrain subsystem design

Prototype and pre-production EV validation

Lightweighting and cost optimization studies