Industries

Contact with

us for any

Design Solutions

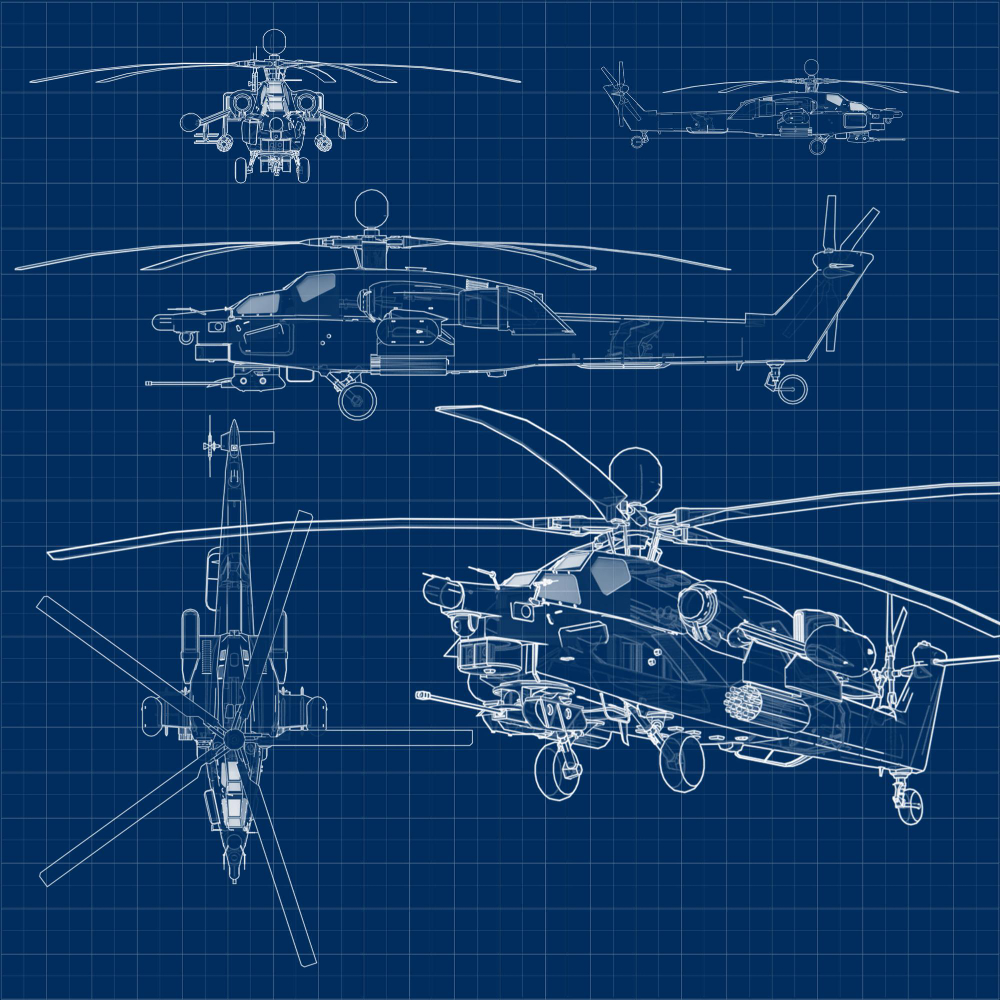

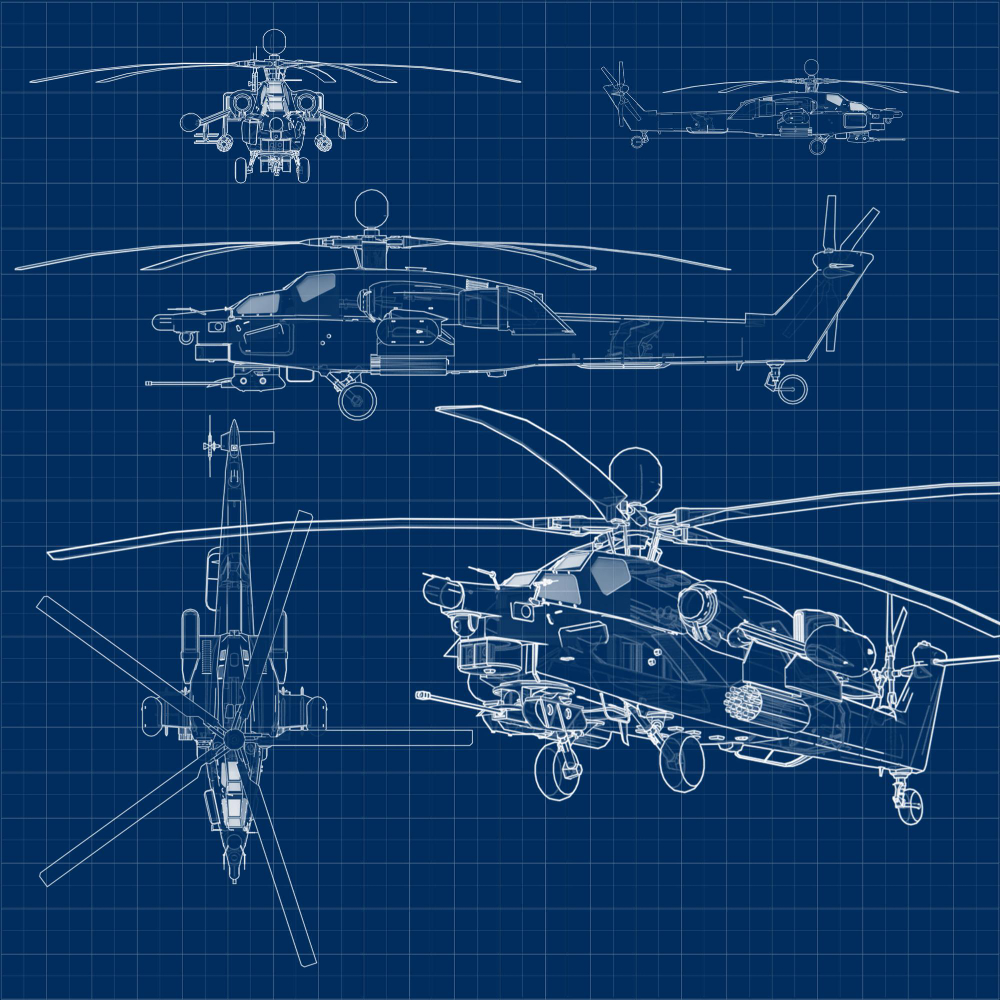

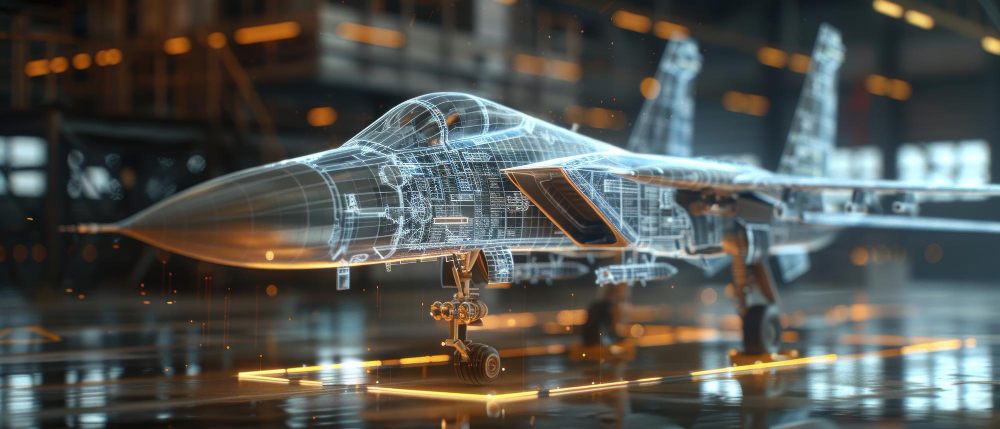

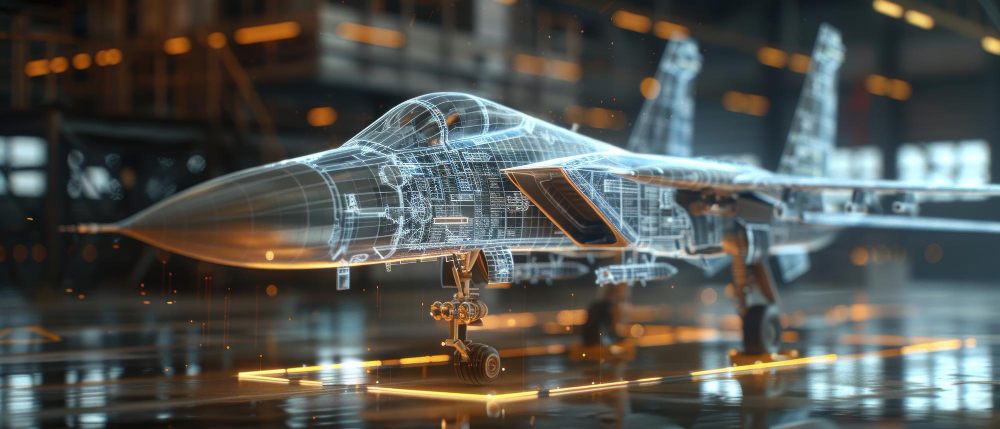

Precision Engineering for Mission-Critical Applications

At Lamis Technology, we deliver advanced aerospace and defense engineering solutions that meet the highest standards of safety, precision, and reliability. Our team of experts supports OEMs, Tier 1 suppliers, and defense organizations with design, simulation, and manufacturing engineering services that comply with international aerospace norms.

We specialize in structural design, subsystem integration, CAE simulation, and tooling development for aircraft, defense vehicles, and high-precision assemblies. Every project we deliver adheres to stringent validation and traceability requirements essential for mission-critical operations.

What we do

Our Capabilities

Aerospace Structural Design: fuselage, wings, pylons, control surfaces, and interior components engineered for strength and weight optimization

Defense Vehicle Engineering: armored structure design, mobility system integration, and survivability analysis

CAE & Simulation: static and dynamic load simulation, crash, fatigue, vibration, and thermal performance studies

Tooling & Fixture Design: jigs, grippers, and welding fixtures for airframe and defense equipment manufacturing

Manufacturing Engineering: process layout, robotic automation, and digital twin validation for precision assembly

Documentation & Compliance: design data management, validation reports, and regulatory traceability

Toolchain

Deliverables

Measurable benefits

Use cases we support