Industries

Contact with

us for any

Design Solutions

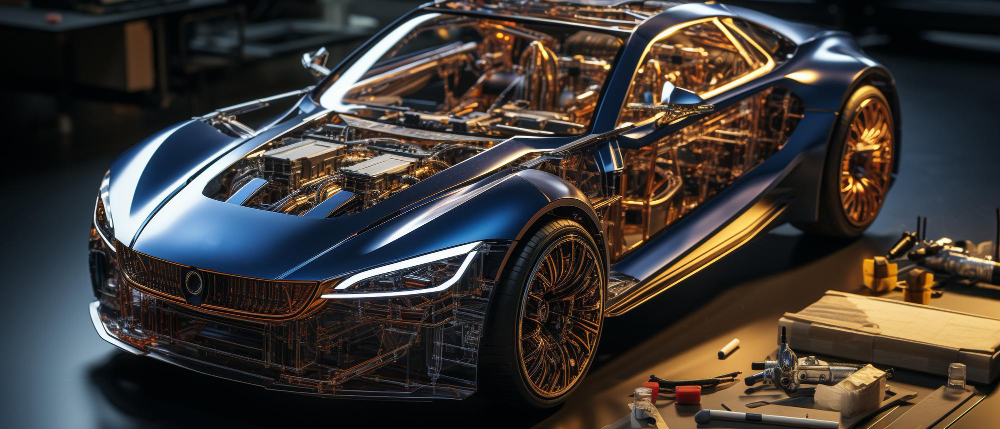

Automotive Design and Engineering Solutions

Lamis Technology partners with global OEMs, Tier 1 suppliers, and mobility startups to deliver precision engineering from concept to production. Our teams combine domain expertise with advanced CAD and CAE to create safer, lighter, and smarter vehicles across ICE, hybrid, and EV platforms. We reduce development time, control cost, and raise product quality through a rigorous, model-based approach and validated manufacturing processes.

What we do

Our Capabilities

Vehicle architecture and body systems: BIW, closures, exterior and interior trims, sealing, crash energy management

Chassis and dynamics: suspension, steering, braking, subframes, mounts, kinematics studies

Powertrain and drivetrain: ICE packaging, e-axles, EDU, battery and thermal packaging, NVH refinement

CAE and simulation: FEA, NVH, crash and occupant safety, durability and fatigue, thermal and CFD, tolerance stack-up

Value engineering: should costing, benchmarking, lightweighting, design for manufacturability and serviceability

Manufacturing engineering: BIW welding fixtures, stamping dies, assembly jigs, checking fixtures, material handling solutions

Data and lifecycle: change management, configuration control, BoM alignment, release and documentation

Toolchain

Deliverables

Measurable benefits

Use cases we support